MayAir is the trusted partner for North American Li-ion battery manufacturers seeking cutting-edge cleanroom solutions that guarantee optimal air quality, particle control, and sustainability. Elevate your battery manufacturing facility to meet industry-leading cleanliness standards and deliver safe, reliable energy storage solutions for a greener future.

MayAir specializes in offering customized air filtration and cleanroom solutions that effectively cater to the specific requirements of the Li-ion battery sector.

MayAir is a leading provider of cleanroom solutions tailored for the lithium-ion battery industry. We ensure optimal air quality and particle control during battery production to prevent contamination. Our energy-efficient solutions support sustainability and help reduce carbon footprint—partner with MayAir to meet industry cleanliness standards and deliver safe energy storage solutions for a greener future.

Navigating the Li-ion Battery Landscape

Li-ion Battery Americas 2024 exemplifies the collective effort to expedite the development of EV and Li-ion battery technologies, fostering collaboration among policymakers, investors, manufacturers, and technical service providers.

As the forefront of technological evolution and sustainable energy solutions, lithium-ion batteries have revolutionized industries, reshaping transportation and energy storage paradigms.

From powering electric vehicles to enabling grid stabilization with renewable energy, Li-ion batteries are driving the transition towards a greener and more sustainable future.

United States Lithium-ion Battery Market

According to recent market research, the United States leads the North American region in lithium-ion battery market size, with significant growth projected in the coming years. With the market revenue expected to reach USD 35 billion by 2028, driven by the increasing adoption of electric vehicles and stringent government regulations on greenhouse gas emissions, there has never been a more critical time to invest in cutting-edge filtration solutions.

As the demand for lithium-ion batteries surges across North America, MayAir stands ready to support your journey towards sustainable energy solutions.

With our extensive range of advanced filtration technologies, we are your trusted partner in ensuring your battery manufacturing processes’ efficiency, purity, and longevity.

The Role of Filtration in Battery Manufacturing

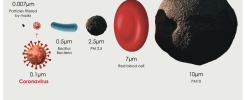

Within the intricate processes of Li-ion battery manufacturing, maintaining cleanroom integrity is paramount to ensuring product quality, performance, and safety.

Vacuum systems play a pivotal role in various stages of battery production, from raw material handling to final sealing, where they facilitate material purity, precision, and consistency.

However, these processes also generate contamination, posing risks to battery performance and safety. Purpose-built filtration solutions are essential for capturing contaminants, protecting vacuum systems, reducing maintenance costs, and ensuring uninterrupted operations in this 24/7 industry.

The Importance of Cleanroom Solutions for Lithium-Ion Battery Manufacturers in North America

- Product Quality and Safety: Lithium-ion batteries are sensitive components prone to contamination by dust, moisture, and other airborne particles. These contaminants can lead to defects, malfunctions, and even fires. Cleanrooms provide a controlled environment that minimizes these risks, ensuring consistent, high-quality and safe battery production.

- Compliance with Regulations: Battery manufacturers in North America must adhere to strict regulations set forth by organizations like the Environmental Protection Agency (EPA) and the Occupational Safety and Health Administration (OSHA). These regulations often mandate specific air quality standards within production facilities. Cleanrooms with proper filtration systems help manufacturers comply with these requirements.

- Process Efficiency and Cost Reduction: Contamination in battery production can lead to rejected batches and production delays. Cleanrooms minimize this risk, leading to smoother operations, reduced waste, and lower production costs.

- Advanced Battery Technologies: Lithium-ion battery production trends towards higher energy densities and next-generation technologies. These advancements require stricter contamination control measures that can only be achieved with effective cleanroom solutions.

Contamination poses significant challenges to Li-ion battery performance and safety. Metallic impurities can lead to internal short circuits and thermal runaway, endangering battery integrity.

Research findings suggest that contaminants disrupt battery performance by directly reacting with lithium and interfering with the formation of the solid electrolyte interface (SEI).

Moreover, the environmental impact of battery production and disposal, including the mining and processing of materials and emissions during transportation, underscores the urgency of sustainable practices in the industry.

MayAir’s Circular Approach

At MayAir, we are committed to empowering sustainable solutions that not only optimize cleanroom performance but also minimize environmental impact.

Our circular approach focuses on the eco-friendly design, production, and disposal of filtration products, ensuring a closed-loop system that reduces waste and conserves resources.

By prioritizing sustainability throughout our operations, we strive to create a cleaner, greener future for the Li-ion battery industry and beyond.

Why Partner with MayAir?

1. Elevate Your Cleanroom Standards: From FFU (Fan Filter Unit) and wall panels to raised floors and air showers, we offer a full range of filtration solutions tailored to ensure peak performance in your Li-ion battery manufacturing cleanroom.

2. Advanced Technology: Our state-of-the-art filtration technologies ensure optimal performance, material purity, and consistency throughout your production processes, ultimately leading to higher battery power, energy density, cycle life, and charging speed.

3. Reliable Performance: MayAir’s filtration solutions are engineered to deliver consistent and reliable performance, ensuring the highest standards of cleanliness and air quality in your Li-ion battery manufacturing cleanroom.

4. Customized Solutions: We understand that every cleanroom has unique requirements. MayAir offers customized filtration solutions tailored to the specific needs and challenges of your cleanroom environment, ensuring maximum efficiency and effectiveness.

5. Proven Track Record: With a track record of success and satisfied clients in the Li-ion battery manufacturing industry, MayAir has built a reputation for excellence and reliability in delivering top-notch filtration solutions.

6. Commitment to Sustainability: MayAir is committed to sustainability and environmental responsibility. Our filtration solutions are designed to minimize energy consumption and waste generation, helping you achieve your sustainability goals while maintaining superior cleanroom performance.

7. Comprehensive Support Services: Beyond product offerings, MayAir provides comprehensive support services, including installation, maintenance, and ongoing technical support, to ensure seamless integration and long-term success for your cleanroom operations.

Partnering with MayAir means investing in quality, reliability, and excellence for your Li-ion battery manufacturing cleanroom.

MayAir’s Lithium Battery Job References

At MayAir, our expertise in providing cleanroom solutions for the Li-ion battery industry is demonstrated through numerous successful projects.

We have partnered with leading battery manufacturers to optimize cleanroom performance and ensure the highest standards of quality and safety. Some of our notable job references include:

For example Project X: Collaboration with a major Li-ion battery manufacturer to design and install customized cleanroom solutions, resulting in improved efficiency and product quality.

For example Y: Implementation of advanced filtration technologies in a battery manufacturing facility, leading to a significant reduction in contamination-related issues and downtime.

For example Z: Provision of ongoing maintenance and support services for a Li-ion battery cleanroom, ensuring seamless operations and compliance with industry standards.

Take Action Today!

For personalized consultations, technical support, and inquiries about our air filtration and cleanroom solutions, we encourage you to reach out to our experts.

With years of experience and expertise in the Li-ion battery industry, our team is dedicated to providing you with innovative solutions that meet your unique needs and challenges.

As the demand for Li-ion batteries continues to grow, now is the time to invest in cleanroom excellence with MayAir. Together, let’s shape a cleaner, greener future for North America and beyond.

Don’t let contaminants compromise the quality and efficiency of your battery production. Partner with MayAir for innovative filtration solutions that deliver results you can trust.

Together, let’s power the future of sustainable energy with MayAir!

With years of experience and expertise in the Li-ion battery industry, our team is dedicated to providing you with innovative solutions that meet your unique needs and challenges. As the demand for Li-ion batteries continues to grow, now is the time to invest in cleanroom excellence with MayAir. Don’t let contaminants compromise the quality and efficiency of your battery production. Partner with MayAir for innovative filtration solutions that deliver results you can trust. Contact us at **https://mayairgroup.com/contact/** to schedule a consultation with one of our experts and power the future of sustainable energy with MayAir!